ALUMINIUM DIE CASTING DEPARTMENT

Aluminium die-casting department is armed with machines of the latest technology. Aluminium die-casting is performed in liquid and semi-solid form (SEMISOLID) in special moulds under pressure in 700°C ±20, while ZAMAC die-casting is performed in 420°C. All die-casting parameters are electronic controlled so to ensure constant quality of casted parts.

Die-casting in semi-solid form (SEMISOLID) is a new generation procedure in which the final product increases the fatigue strength of steel levels. This method is based on the change of the external molecular structure of aluminium which, in order to maintain without return to its physical structure, it has to be casted into semisolid form (SEMISOLID).

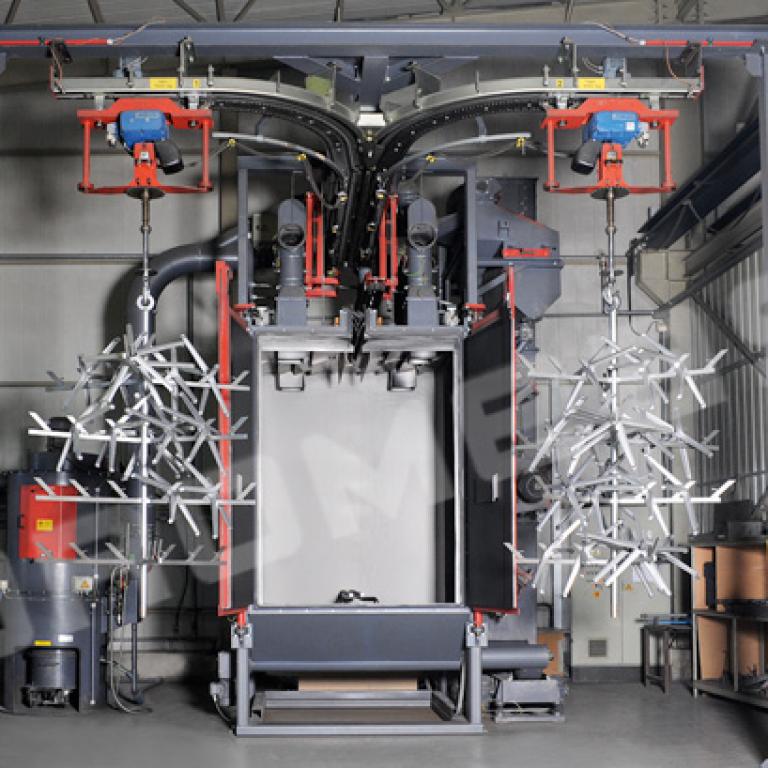

This procedure of die-casting is very specialized and we apply it when we want to substitute heavy parts of steel with light aluminium parts of the same strength with steel (it can be implemented mainly in automotive to reduce the weight of vehicles in combination with metal’s strength maintenance at the same levels). After die-casting it follows sandblast machining, perforation and washing.

The department also has a surface polishing department of aluminium parts with robotic procedure and excellent result. Moreover, the die-casting department is armed with a full laboratory of quality control which includes:

- Composition of raw material analysis

- Fluoroscopy of parts’ internal structure through X-ray

- Complete and accurate dimensional measurement of the components